Blue Star Plastics your reliable outsource partner for quality injection molding and contract assembly.

Full Service Plastic Injection Molding and Contract Assembly

Zero Defects Molding

We provide functional and aesthetic products, color matched units, and parts from a single gram to two-foot square in size. Our parts are produced under a stringent quality system utilizing robotic part handling.

Globally Competitive Assembly

Blue Star Plastics is considered an extension of our customers' manufacturing. We manage vendor networks, install and test circuit boards and wiring harness, decorate products and even provide distribution.

Proven Market Experience

Demanding customers depend on us to understand their needs. APQP, PPAPs, and JIT shipments to the automotive industry; pad printed and functionally tested consumer goods and precision tolerances on industrial programs.

About Us

For nearly 40 years Blue Star Plastics has focused on making our clients more profitable.

At Blue Star Plastics we understand our role in your supply chain. As a full-service plastic injection molder and contract assembly provider we are here to give you a competitive advantage - to get you to market faster, with a better product and to ensure your budgets are achieved. Established in 1984, we are a family-owned business built on a foundation of zero defects production and on-time delivery. We provide close-tolerance precision parts as well as aesthetic color-matched product. While primarily serving the automotive market, we have a diverse background in many industries. Blue Star Plastics is ISO 9001 : 2015 certified with several IATF 16949 compliant processes. Our engineers will help you select the right materials, manage the tool build or transfer, and provide the necessary poka-yoke and assembly processes. Our 5-Gate APQP launch system ensures your project stays on track. Please explore our capabilities and then give us a call to discuss how Blue Star Plastics can help you reach your goals.

Injection Molding

Injection Molding

Your worry-free source for Injection Molding

Our 24 hr./5 days a week injection molding machines are robot equipped and proven repeatable. This provides you competitive pricing and consistent quality results. We process both engineering and commodity resins such as PP, PE, ABS, PC, POM, PA, and elastomers. Our company wide ERP system from IQMS provides real-time monitoring and links every aspect of the process – purchasing, production, quality, shipping, and accounting for transparency and immediate feedback.

Color Spectrophotometer

Ensures color consistency on all parts

Robotic Part Handling

Automated part handling holds down costs and improves consistency

Moisture Analysis

Maximizes the output of the molding process by precisely controlling moisture levels in the resin

On-Site Tool Maintenance

We have an in-house tool room for maximum mold uptime and quick reaction

Contract Assembly

Contract Assembly

We provide Value Added assembly on the majority of our products. Pad-printing, adding screws / clips, applying tape / felt, and even full multi-component assemblies are common deliverables for Blue Star Plastics. Let us help you consolidate your vendor base and inventories by providing more than just a molded part. We are your one-stop outsource connection.

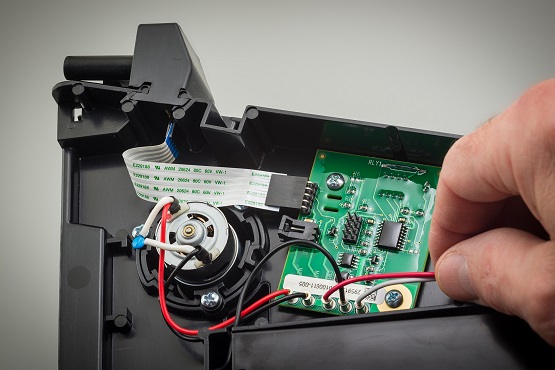

PCB Installation

Handling electronics and wiring harnesses is common

Pad Printing

Pad printing and other decorative options are available

Flexible Work Cells

Scalable production lines can accommodate programs of all complexities

Non-Contact Inspection

High-speed camera inspection ensures the presence of all components

Program Management

We will manage all aspects of your project and get you to market on-time

Functional Testing

Blue Star will work with you to develop custom gauging for your product

Markets

Markets

Industrial

Engineering resins are often used to produce the structural-functional products used in modern equipment and controls. Gears, conveyor components, electrical and power systems, are examples of products we provide.

Consumer

From our first job, a clear cake cover replacing glass, to today's complete assembly of a hands-free paper towel dispenser (including all electronics and sensors), we have worked in the consumer market.

Automotive

Blue Star Plastics serves as a Tier II and III partner with some of the most demanding clients in the world. We provide high-volume interior trim, under-the-hood, and exterior products. PFEMA’s, PPAP’s, Gauge R&R, Kaizen continuous improvement, annual cost reductions and true JIT service are daily activities. When you are ready to discuss your next model year or transfer and existing project give us a call.

Careers

Current Job Openings

Blue Star Plastics has been in business for almost 40 years and we are always on the lookout for new employees to join our family. Our location just off the I-75/I/64 interstates near Loudon Avenue and Russell Cave Road is convenient to downtown Lexington, KY. We offer a stable 24 hour a day - 5 day a week work environment with plenty of opportunity for advancement. If you are interested in joining our team, just clink the link below to start your new career.